What is…?

At Like Technologies, we like it when people ask questions, it’s something we actively encourage across our engineering, administration and leadership teams.

Here, we’ve summarised the most common questions you’ve searched for (and found) on our website in 2022.

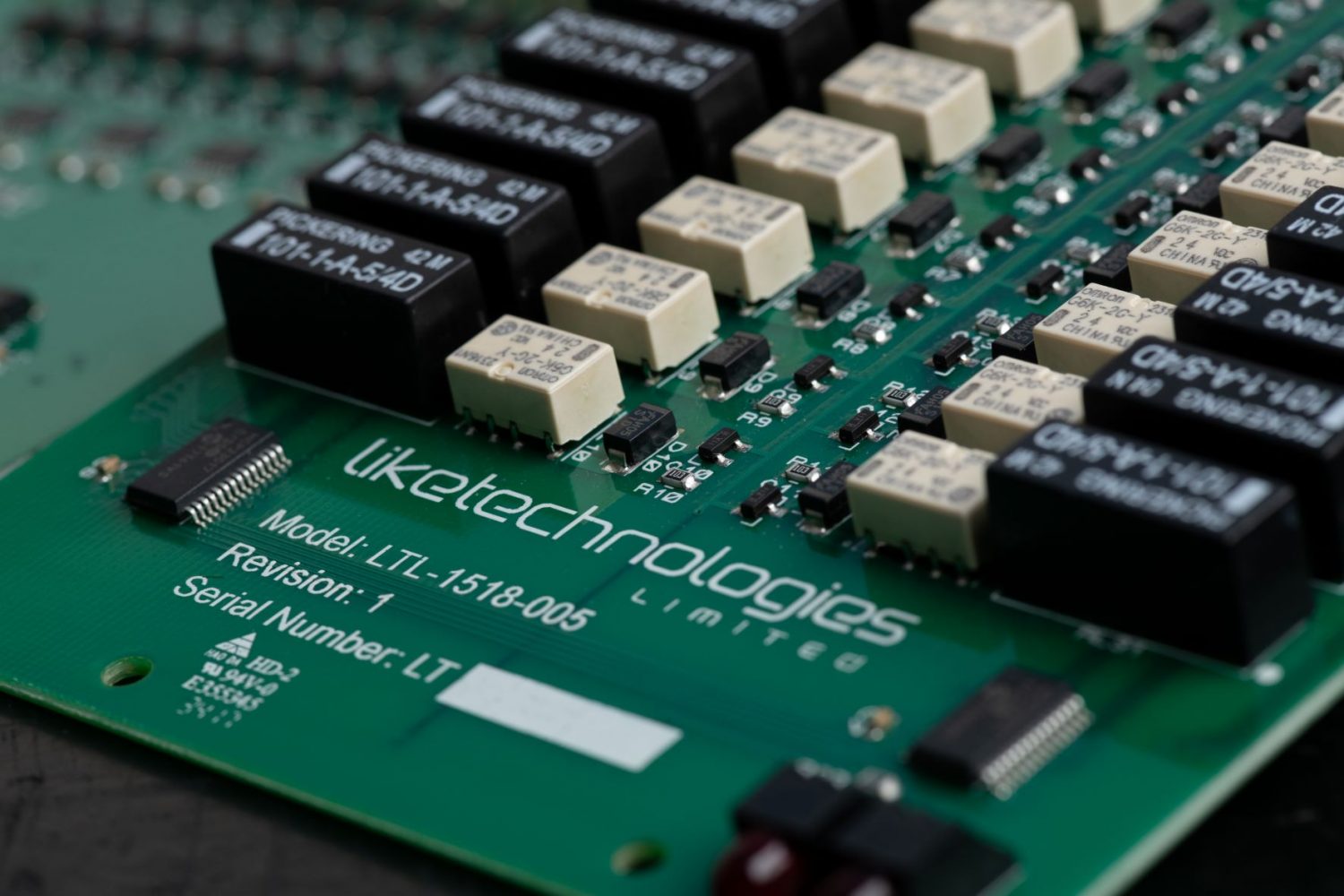

What is the Difference Between Re-engineering and Reverse Engineering?

Re-engineering and reverse engineering are two technical processes which sound similar and are often confused. Both are routinely used in obsolescence management and involve the engineering and further investigation of finished, manmade products. However, the methods used and the desired outcomes differ hugely.

Both re-engineering and reverse engineering play a key part in the obsolescence management solutions we offer to our clients in industry. The processes are a reliable way to redesign or recreate items which are no longer available from the original equipment manufacturer (OEM), even though they are still needed. This allows us to improve upon and bring modules and systems back to life, in compliance with customer specifications and industry standards.

Click here to read about re-engineering and reverse engineering in more detail.

What is Obsolescence Management?

Obsolescence management is a core part of our business. The process involves continually assessing the life span of an element of a system’s lifecycle, whilst planning the replacement of obsolete parts and systems as they age. This must be achieved without posing a threat to productivity or safety, whilst remaining cost-effective. It is an important strategy which requires proactive, strategic and tactical measures to mitigate risk.

In the industry sectors in which we work, ‘obsolescence’ doesn’t just mean the process of becoming outdated. It is the critical transition where parts or resources from the original manufacturer become unavailable, even though they are still needed. Obsolescence must be carefully managed so it doesn’t have a negative impact on productivity – particularly in the power generation sector when the country depends on our clients for light and warmth.

Click here to read about obsolescence management in more detail.

What is a Nuclear Power Station Reactor Outage?

Nuclear power station reactor outage periods fall into two categories, forced and statutory. Forced outages occur due to emergency reasons or unanticipated breakdowns that can’t be dealt with while the reactor is at power. Statutory outages are scheduled and are a legal requirement enforced by the Office for Nuclear Regulation (ONR). These outages are shutdowns in which activities are carried out between the disconnection and re-connection of units to the electrical grid.

Statutory outages are an opportunity to repair, maintain or test equipment that cannot be accessed when a reactor is at power. It is important that the UK’s existing nuclear power stations stay functional and continue producing low carbon electricity for as long as it is safe to do so. Outage periods provide the chance to ensure that plant performance is safe and optimal in terms of high availability, environment preservation and costs.

Click here to read about outages in more detail.

What is Electech?

Electech is the name given to the innovative industry sector producing the electronics and electrical hardware which is essential for the existence of technology. This sector is hugely significant to the future of the UK’s economy and has a strong presence right here in the north west of England.

Electech consists of electronics, electrical, electro-technical hardware and embedded software (low-level software that controls hardware). These are combined to create boxes of electronic and electrical hardware and the embedded software which controls them, known as embedded systems. Examples vary hugely but include everything from flight control systems in aircrafts, right down to your Amazon Echo!

A strong Electech sector and industry leadership increases the UK’s power to export globally and attracts direct investment from abroad. There are so many opportunities for innovation, including the Internet of Things, embedded security, AI and 5G communications. UK companies have the knowledge and capability to impact the world and will play a foundational role in the development of future industries and value chains.

Click here to read about Electech in more detail.

What happens when your original equipment manufacturer no longer supplies your equipment?

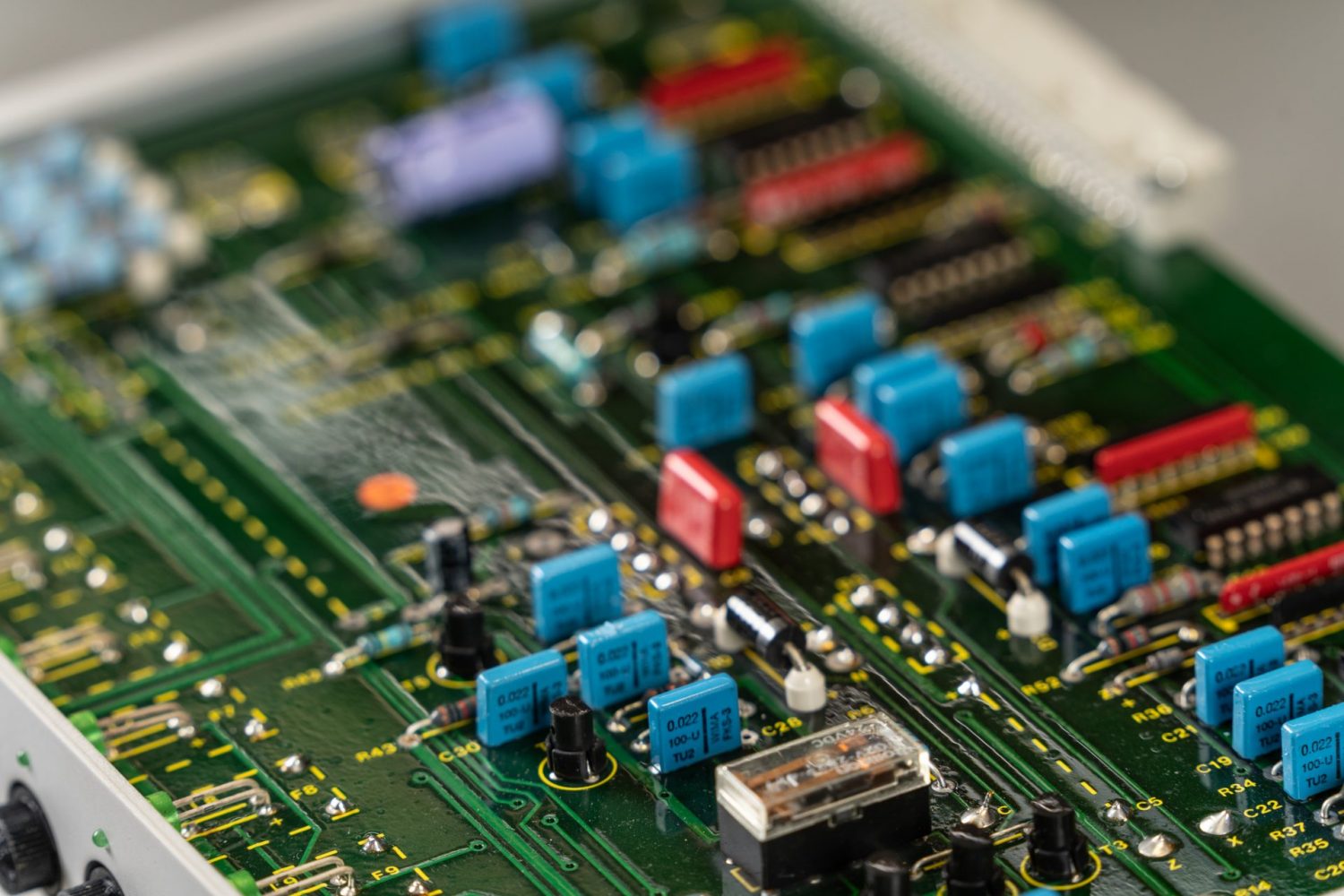

It’s common within industrial environments to still operate legacy equipment. To update existing equipment can be time-consuming and costly. Yet what happens when your original equipment manufacturer (OEM) no longer supports or supplies the equipment you use?

Ageing and obsolescence of said equipment then becomes a risk to your business, as it may not be able to continue operating reliably or safely. This became the case for one of our customers who had some existing modules that needed refurbishment in order to continue using them.

Our customer required the evaluation, assessment and refurbishment of a range of analogue control modules at two different sites, as part of a larger plant life extension programme. The equipment dates from the 1980s, comprising of a range of rack-mounted analogue electronic function and signal conditioning modules in a range of configurations, with accompanying power supplies and operator interfaces.

Have you got a question that we’ve not answered? Send it to info@liketechnologies.co.uk.