What happens when your original equipment manufacturer no longer supplies your equipment?

It’s common within industrial environments to still operate legacy equipment. To update existing equipment can be time-consuming and costly. Yet what happens when your original equipment manufacturer (OEM) no longer supports or supplies the equipment you use?

Ageing and obsolescence of said equipment then becomes a risk to your business, as it may not be able to continue operating reliably or safely.

This became the case for one of our customers who had some existing modules that needed refurbishment in order to continue using them.

The ageing equipment and its background

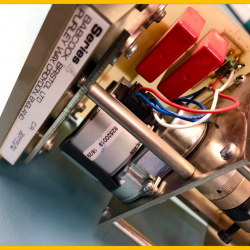

Our customer required the evaluation, assessment and refurbishment of a range of analogue control modules at two different sites, as part of a larger plant life extension programme. The equipment dates from the 1980s, comprising of a range of rack-mounted analogue electronic function and signal conditioning modules in a range of configurations, with accompanying power supplies and operator interfaces.

The OEM (Babcock Bristol Limited) no longer manufactures or provides support for these devices meaning the customer could no longer continue to operate them reliably, without the associated ageing and obsolescence risks involved.

How did module refurbishment solve the problem?

We conducted a comprehensive ageing and obsolescence evaluation, design review, test procedure generation and refurbishment of the modules across our customer’s sites.

The work package included the evaluation of 42 module types covering input and output conditioning and controlling function, assessment of available options, risks to continued support and defined available mitigation measures.

A full refurbishment and delivery plan for 372 modules was developed with our recommendations for long-term maintenance, support and storage. Throughout the whole process, our customer’s system and QA engineers reviewed the quality of the documentation and the refurbished modules.

This robust, and detailed piece of work offered a cost-effective alternative to re-engineering or wholesale replacement.

Like Technologies Ltd specialise in ageing equipment and legacy systems, whether that be refurbishment, re-manufacture or event creating new bespoke hardware designs to replace original equipment.

If you have a piece of equipment whose OEM is no longer in operation or no longer supports that age of model do not hesitate to give one of our skilled engineers a call on 01524 811 383 to discuss how we can help. You can also visit our website www.liketechnologies.co.uk for more information.