Obsolescence Management

How Repairing Electronic Modules Keeps The Power Generation Industry Going

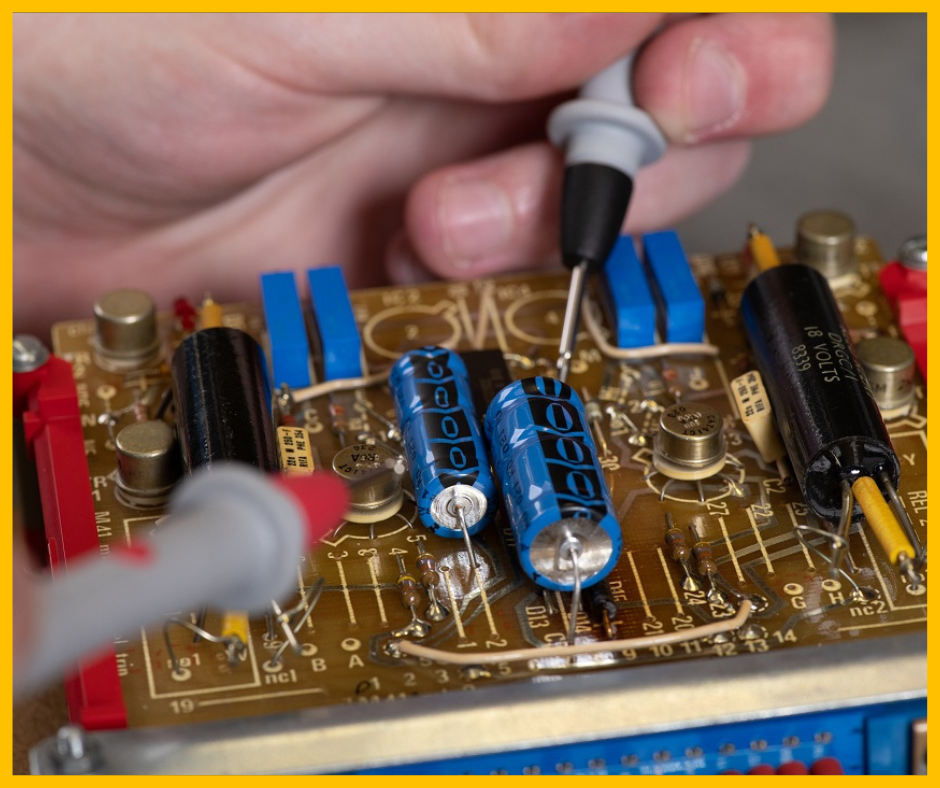

The power generation industry, and more specifically, nuclear power often relies on legacy software and systems to keep their sites running. These industries constantly face pressure to extend the functional lifetime of their older equipment, more specifically electronic modules due to the huge investment and upheaval it would take to simply replace the entire system.…

Read MoreCase Study: Using Bespoke System Design to combat Obsolescence

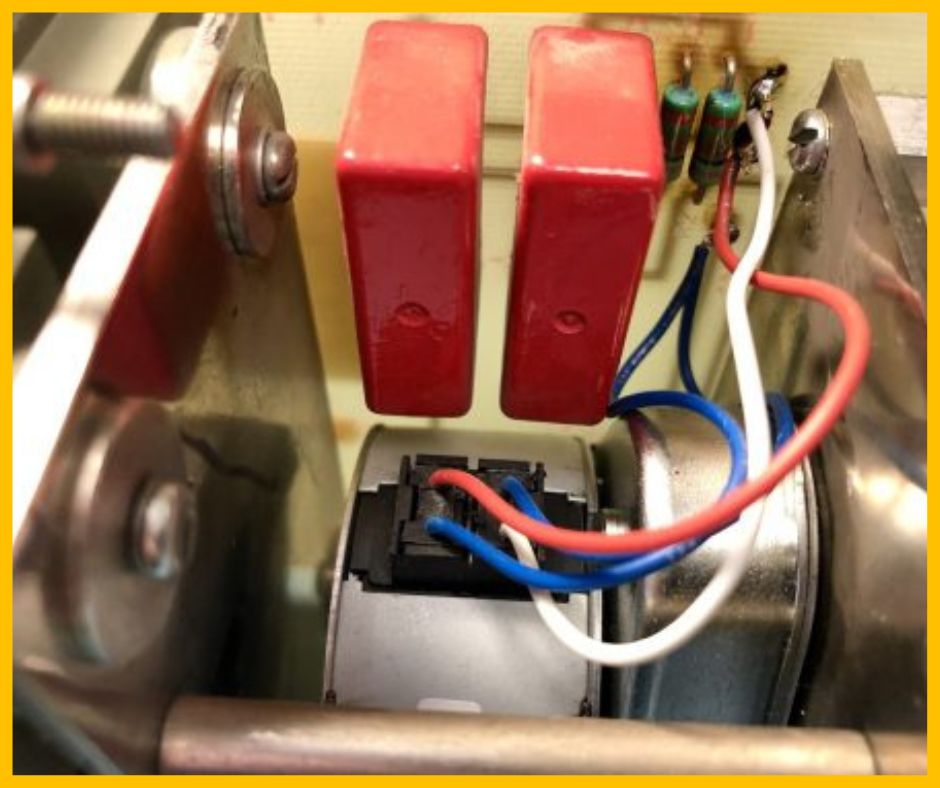

Our client needed to mitigate issues surrounding ageing plant equipment across their fleet. One such issue was identified within the EPPE (Essential Plant Protection Equipment) ROP B system. The system modules contain components that have become obsolete making repair difficult and sometimes impossible. As a Class 1 high integrity system, EPPE ROP B is essential…

Read MoreIndustrial Electronic Repairs Help to Generate Net Zero

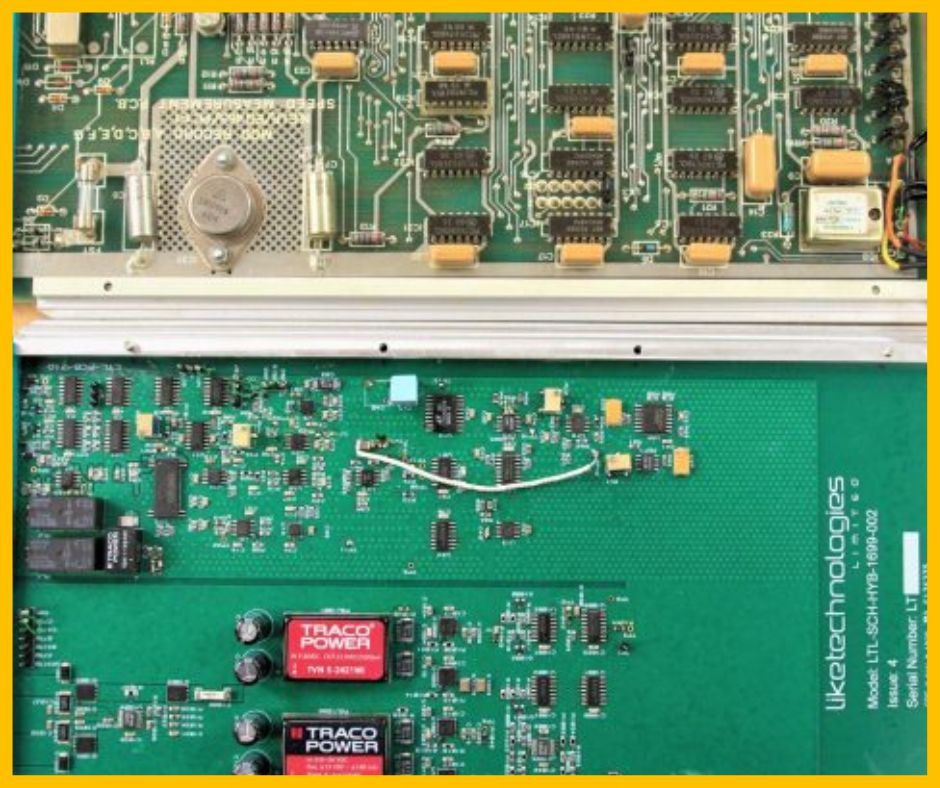

Industrial electronic repairs, such as those carried out by Like Technologies to support operators of control systems, are helping to extend the life of existing Advanced Gas-cooled Reactors (AGRs) supplying low carbon energy while newer alternatives are established. What is Net Zero? Net Zero is an increasingly popular term that has been widely publicised in…

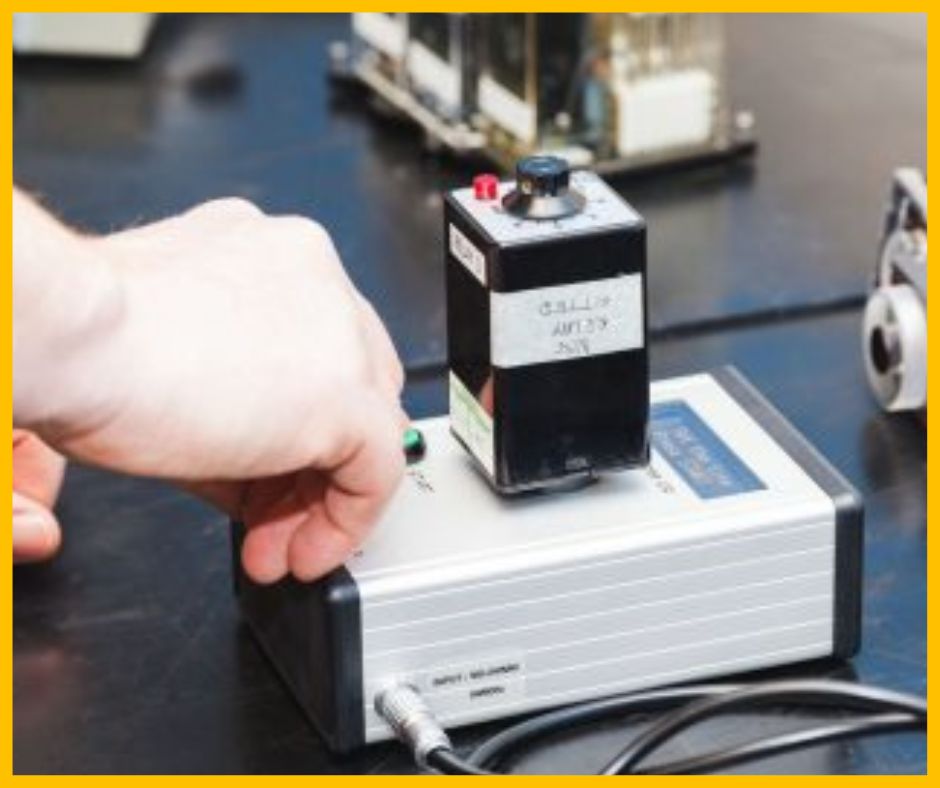

Read MoreWhat is the Difference Between Re-engineering and Reverse Engineering?

Re-engineering and reverse engineering are both routinely used in obsolescence management. Here we explain the difference between the two technical processes.

Read MoreWhat is Obsolescence Management?

Obsolescence is a growing and significant threat to industry in the UK. Here, we explain what obsolescence management is and discuss our tailored approach.

Read More