How Repairing Electronic Modules Keeps The Power Generation Industry Going

The power generation industry, and more specifically, nuclear power often relies on legacy software and systems to keep their sites running. These industries constantly face pressure to extend the functional lifetime of their older equipment, more specifically electronic modules due to the huge investment and upheaval it would take to simply replace the entire system.

As an example, one of our customers EDF Energy, whose fleet of advanced gas-cooled reactors were built in the 1970s and 80s, is often faced with the challenges presented by the ageing of this equipment. Understandably as this equipment ages, many of the components begin to deteriorate, increasing failure rates.

The rapid change in technology has meant that many of the devices installed in existing nuclear power plants are no longer being manufactured. With more of the technologies becoming obsolete, the industry has a strong reliance on repair, refurbishment and obsolescence management skills.

Whilst maintaining safe and reliable plant operation is the number one priority, to upgrade or re-install new systems and hardware would be costly, time-consuming and ultimately impact the availability of power. Alternative solutions are often sought after so that nuclear power plants can continue safe operation without unplanned shutdowns.

Repairing Electronic Modules and Components

In a typical industrial environment, it is increasingly common to replace damaged or defective electronic modules so that operation can continue. When an assembly or individual PCB fails, the end-user often attempts to find a replacement, only to discover that it is obsolete or too expensive.

When failures do occur, it is most commonly at component level and when these critical parts aren’t available this significantly increases the time it takes to return to service. What’s more, the skills and facilities that are required for component level maintenance are often quite different than those required for whole part level maintenance- that’s where Like Technologies comes in.

The Challenge of Obsolescence Management

Managing the repair work of these electronic modules is more than just providing spare parts. Continuing safe operation of the nuclear power plant without unplanned shutdowns must be taken into consideration.

On the occasion that like-for-like replacements of modules are not available, the process of re-engineering from design to approval can take considerable time. These challenges need to be proactively managed in order to maintain safe and reliable plant operation.

Managing obsolescence doesn’t just mean carrying a large stock of obsolete parts, changes in performance or regulatory requirements need to be taken into consideration and simply investing in a large inventory of spare stock is not an option.

At Like Technologies, we can assess your repair needs on a case by case basis, and offer you the skills required to maintain parts at component level.

Our Repair Services

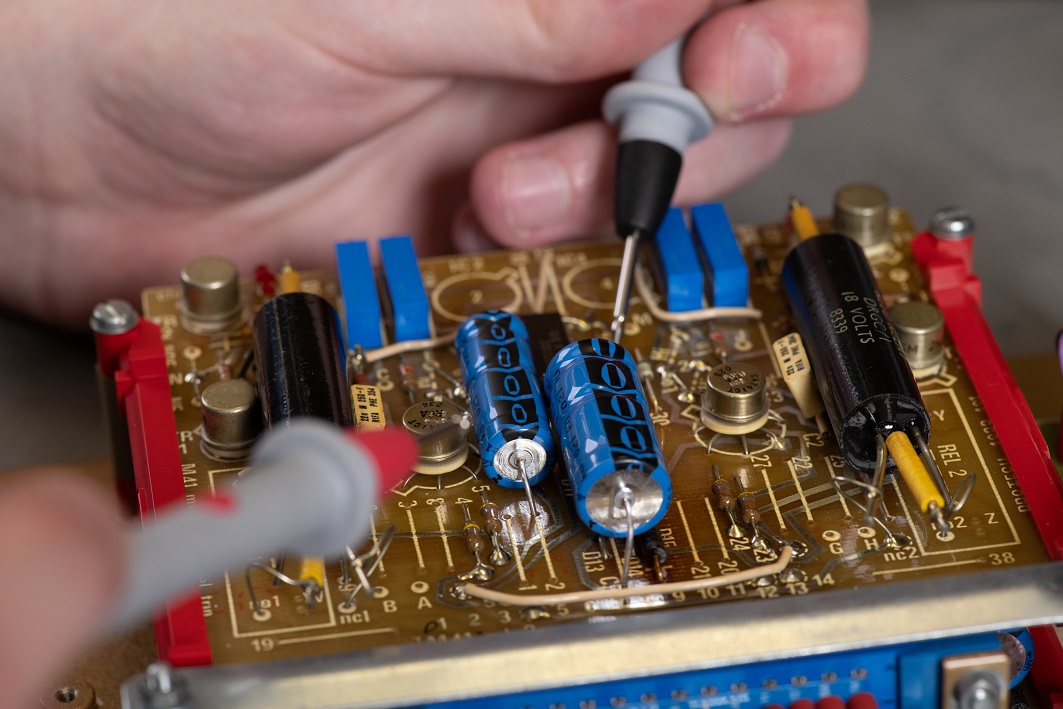

Like Technologies has a proven reputation for repairing and resolving issues with industrial electronic module assemblies. Our team provide a repair, full function test, refurbishment and re-manufacture service on a range of Original Equipment Manufacturer (OEM) assemblies and individually printed circuit boards (PCBs).

All modules are repaired/refurbished to the Rework Modification & Repair of Electronic Assemblies Standard (IPC – 7711 / 7721) and inspected against the Acceptability of Electronic Assemblies Standard (IPC – A – 610).

We currently have a large repair portfolio supporting in excess of 900 different types of modules, from many different manufacturers. Our expert electronics engineers are experienced in repairing most types of items from manufacturers in the industrial sector including:

- Bristol Babcock Ltd

- Kingshill

- Protech

- Penny & Giles

- Siemens

- GEC

- GEM

- Honeywell

We are always keen to speak to new organisations where our expert industrial PCB repair and testing services can provide bespoke, value for money solutions. Get in touch today by visiting our contact page or calling us on 01524 811 383.