Case Study: Using Bespoke System Design to combat Obsolescence

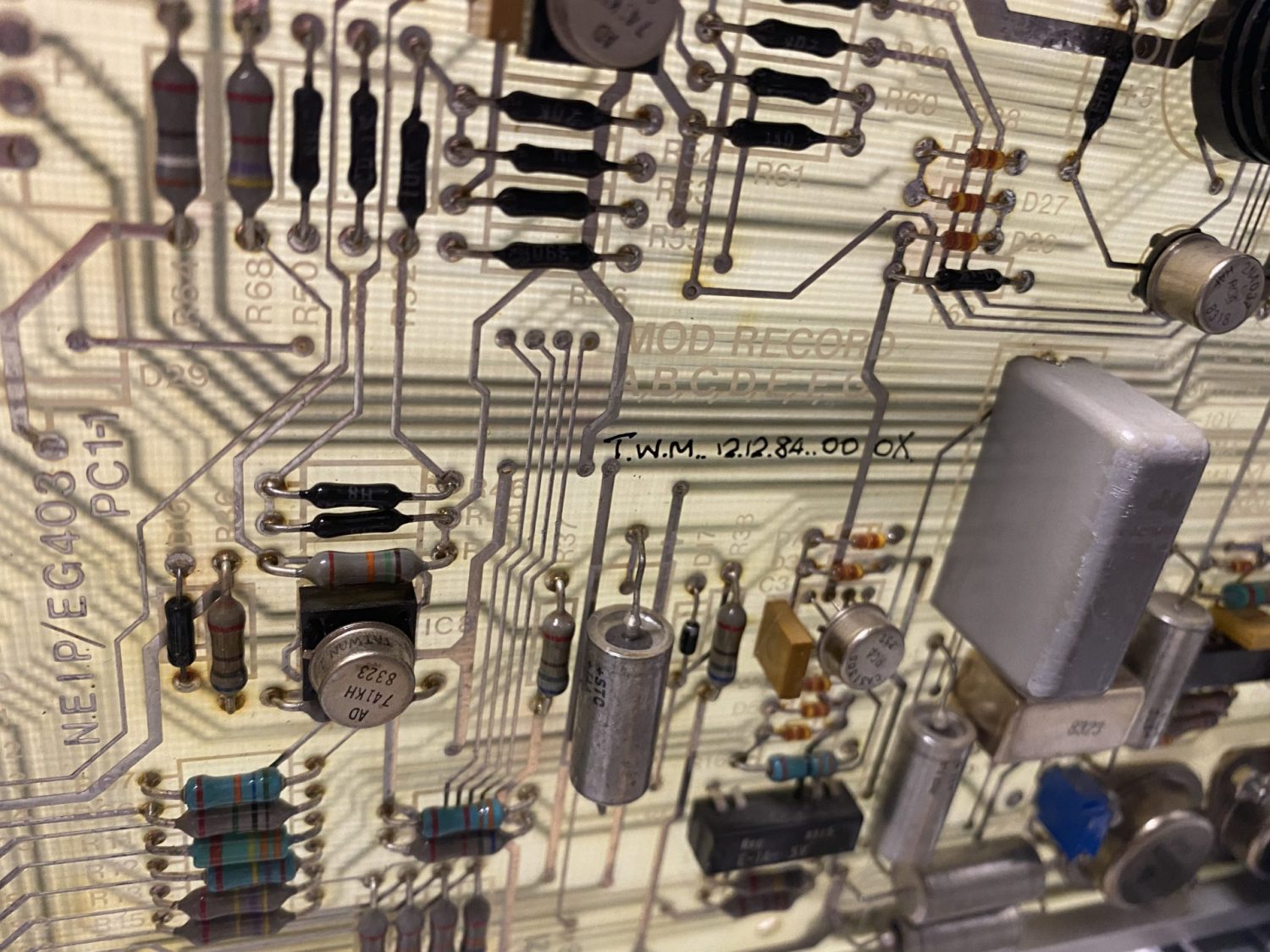

Our client needed to mitigate issues surrounding ageing plant equipment across their fleet. One such issue was identified within the EPPE (Essential Plant Protection Equipment) ROP B system. The system modules contain components that have become obsolete making repair difficult and sometimes impossible. As a Class 1 high integrity system, EPPE ROP B is essential for ensuring plant safety and its reliable running is of top priority. We were tasked with the redesigning of the system in order to produce a like-for-like replacement that would integrate seamlessly with the existing plant and circumvent the problem of obsolescence while complying with strict industry standards and regulations.

Decision-making process

A requirements gathering exercise was held to identify the high-level specifications and functionality of the existing system, aided by the extensive knowledge our engineers have of our client’s plant processes and protocols. Our client highlighted their desire to remove the software element from the system and replace it with a purely hardware-based solution in order to eliminate the potential of errors being introduced by software glitches.

Solution

Once the project scope was agreed upon, we undertook intensive analysis of the existing system to create detailed preliminary designs that replicated the form, fit and function of the original, using modern components that could easily be sourced and installed. The software aspect of the system design was removed and replaced with an entirely hardware-based system that still retained the required functionality of the original.

The new designs were then translated into fully functioning prototypes of the improved system. The prototypes underwent a series of rigorous industry-standard tests to ensure full compliance before the project entered the pre-production phase. Here, final adjustments were made to perfect functionality and performance before the project was carried forward into the full production phase, where the final product was manufactured ready to be integrated into our client’s plant systems.

Results

The new system replicates the functionality of the original with a simplified user interface to give full control to the operative, without the need for complex software. The components used are fully up-to-date and easily sourced in the event of a repair. Additionally, the new system can be installed into the existing plant with no unnecessary disruption to plant function. The redesigned EPPE ROP B system will remain serviceable for the entirety of the plant’s lifecycle, with 20 complete systems ordered to fulfil our client’s requirements.